Keep food fresh, Profits high, and Operations effortless.

“Real-time sensors and predictive analytics from Stratosfy are revolutionizing multi-unit food service operations.”

Slash your repair bills and food costs

Cost Control

Eliminate food safety liabilities and risks

Equip your multi-unit restaurant operation with the tools to stay ahead of equipment issues and compliance challenges. Our streamlined incident workflows enable swift action to prevent costly lawsuits, license risks, and shutdowns stemming from temperature non-compliance.

Experience a paradigm shift in your compliance journey with Stratosfy’s intelligent platform. Gain peace of mind knowing you can adhere to regulations with confidence, thanks to precise temperature reports and efficient incident management workflows.

Achieve uniform equipment monitoring across locations

Consistency

Consistency is critical to success in the intricate world of multi-unit operations. Yet, achieving uniformity across diverse locations is challenging due to varying equipment, maintenance needs, and compliance standards. Traditional methods like standard operating procedures and regular inspections often lead to inefficiencies and risks, especially in temperature monitoring.

With Stratosfy by your side, embrace the power of consistency to achieve uniform food quality and operational efficiency and bolster your brand reputation and customer trust across your entire operation.

Stratosfy Equipment Operations Platform

The World's First Connected Platform for Multi-Unit Restaurant Leaders

Equipment Operations Platform

Customer Success Stories

Stratosfy's proactive alerts and actionable insights keep us ahead of issues, ensuring we can tackle any challenge with confidence.

Stratosfy's automated temperature monitoring has cut our restaurant's repair costs by enabling prompt issue detection and prevention, ensuring smooth operations.

I get temperature logs from my locations into my inbox every day, there by eliminating the need for travel to review temperature logs. I can have remote oversight efficiently.

Stratosfy's platform detected a temperature spike in our refrigeration unit and identified a possible leak. The immediate alert allowed us to address both issues quickly, preventing a potential disaster.

We have gone with Stratosfy's platform for our restaurants as we found their sensors reliable and platform comprehensive. My team can now monitor different types of equipment and stay ahead of issues.

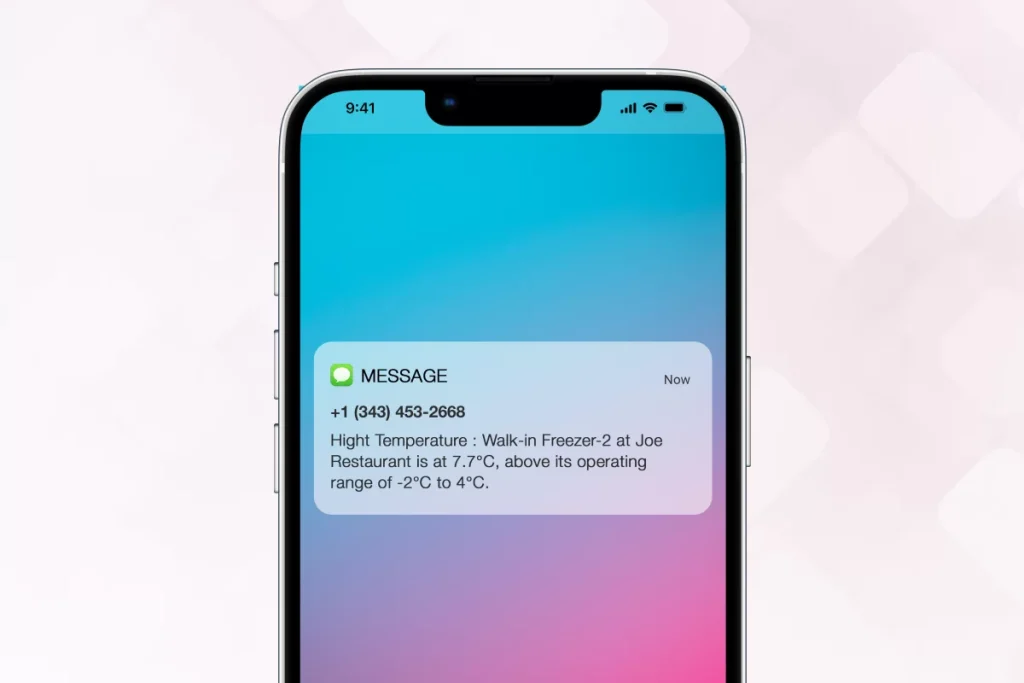

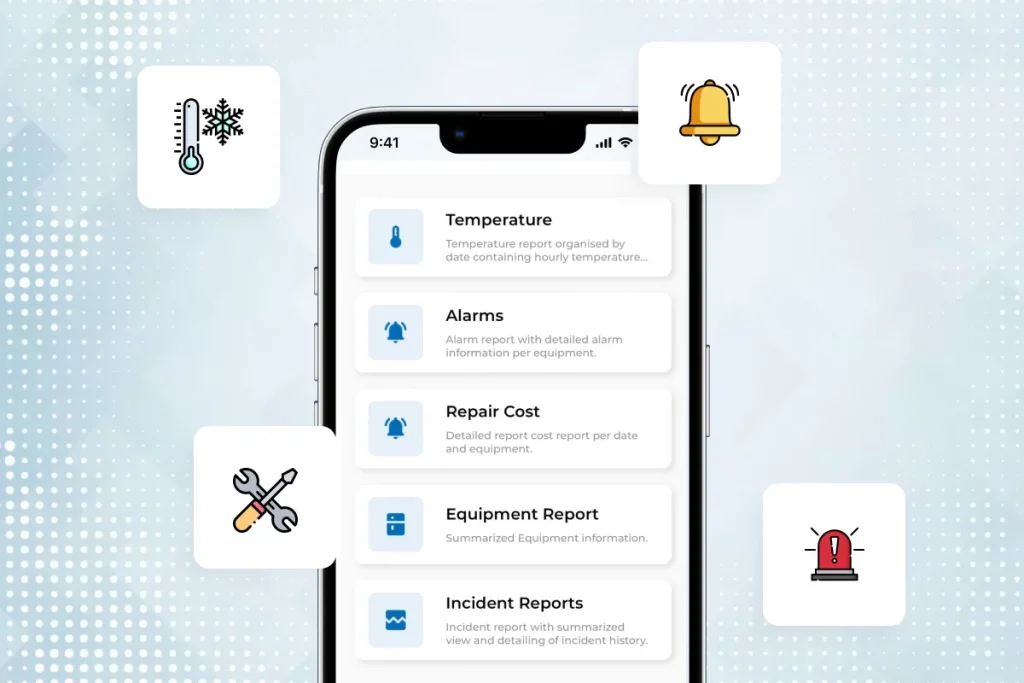

I use Stratosfy's mobile app to keep an eye on my equipment temperatures and act on them promptly. What i liked about the platform is it does not overwhelm you with notifications but raise notifications only when there is a problem.

With Stratosfy's platform, I completely eliminated my manual temperature logging practice and improved accuracy and efficiency in managing my logs.

I can have a snapshot of all my equipment from the Stratosfy web dashboard and also can monitor temperature trends over the day through daily scheduled reports i receive on my e-mail.

I can have my staff now spend the time they were spending on temperature logs to serve customers and improve the guest experience for my customers.

When the public health inspector saw that we are using automated temperature monitoring system, his confidence on our overall operations increased. We selected Stratosfy platform for their easy-to-use UI and suitability of their sensors to all types of refrigeration equipment that we have.